I never was a foodie. I always viewed an obsession with food as unhealthy. Then I had two revelations:

- I don’t live in a foodie culture. I live in an over-indulgence culture. That I can’t order a lunch anywhere and be without leftovers is indicative of this. When our agricultural system was streamlined and ownership consolidated, with production determined by government subsidy, we ended up with vast quantities of high-calorie and low-quality food–product that needs to be moved. So food is cheap but not good. We compensate by adding addictive flavor enhancers, then eating too much. When contrasted with true foodie cultures, the ones that refuse to lower quality, we end up with small and expensive portions, that are overall lower in calories and additives, which also taste better naturally. And we ridicule these people relentlessly (damn French!)

- Being descended from western European immigrants, the food I grew up with was of traditional peasant variety. This alone didn’t make the food bad, but coupled with a lower middle class childhood, my mother’s food didn’t generally branch out into the more exotic ingredients out of basic economics. And her own upbringing instilled the value of food being simply available, so to her standpoint being a foodie was having sufficient quantities and eating a lot. And shut up and eat, because starving children in China.

These two points continually boost each other, and whether we blame capitalism or economic limitations as the initiator, the end result is that American middle class food culture is one of excess over quality.

But then I developed the technical skills required for cooking, and while my formative financial station kept me locked in the familiar mediocrity, my socioeconomic ladder-climbing provided exploratory means. I realized that cooking, like any technical skill, could be quite rewarding when also risking failure (something money allows). I argue with people on the true artistry of food preparation, but I don’t think many of us achieve that level. We are not chefs. We are cooks, executing known techniques to output a palatable result, which is not to say that the process is easy to learn, or not fun and interesting.

But enough of my sociological babble. That was just an intro so I could show what I’ve been up to on the food front.

…which amusingly begins with peasant food!

Potatoes, onions, blood sausage, sauerkraut, and dumplings. That’s pretty peasanty all right. Filling and hitting all the macronutrients. This was mainly to try the blood sausage, which I had never had before. Like liver, it was unsurprisingly very rich and iron-y. It was okay, but I don’t think I’ll get it again.

Next up, bread, which I don’t think qualifies as peasant food. It predates that, being a standard subsistence food for humanity and the reason for agriculture’s genesis. Well, that and beer. Both cereal crops though.

But, this is no simple bread. This is sourdough, and a wild strain at that.

Bread freaks go on and on about this–about how sourdough yeast is unique to the geographical region and by baking with it, the essence of said region has been captured. However true that may be, it sounds a little too fanciful for some damn bread. But it still holds an ounce of coolness, that I now posses the knowledge to create bread sans commercial yeast. And unlike commercial yeasts, this one had a much stronger flavor. I’ll try to keep that mother alive (the yeast one–the other one’s on her own).

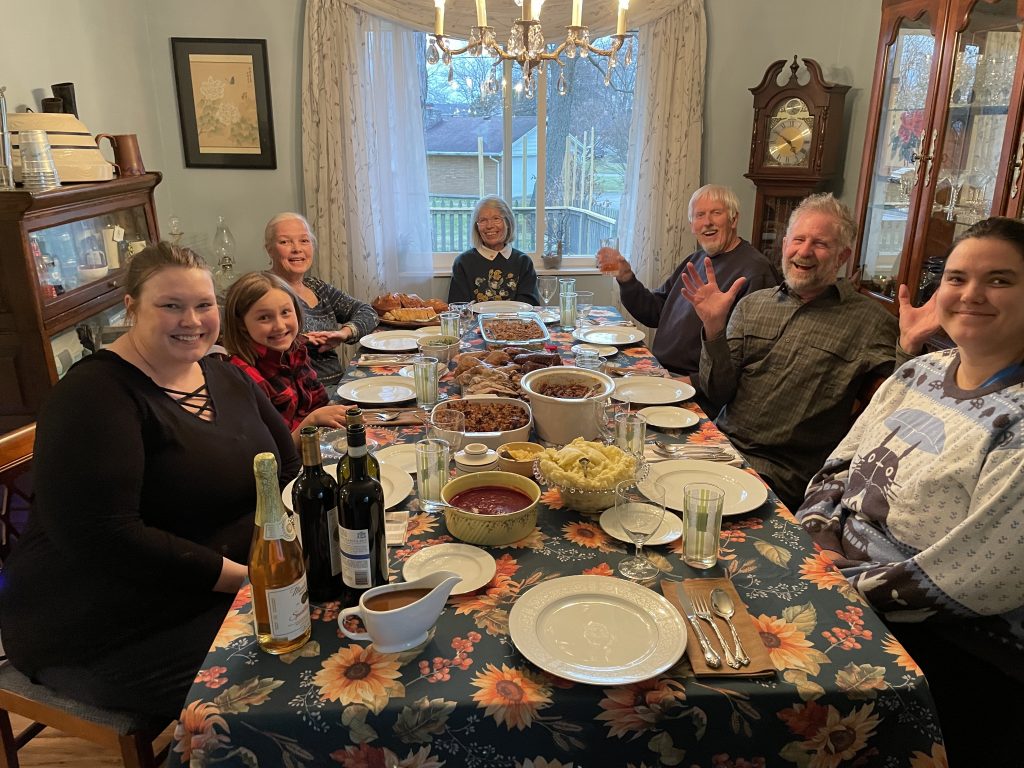

And next, some more smoking successes. While I can’t claim the other dishes on this table, I did smoke a turkey for the first time, to positive reviews. I don’t know where exactly turkey fits in on the status scale, because it’s a holiday tradition food, so maybe it’s exempt altogether.

Turns out that smoking is indeed a viable cooking method. I’ll try frying one of these years.

And last, also smoked–some more bacon. Pork belly might have originated as low class food, but with its popularity and prices today, I think it achieved haute cuisine. Noveau riche, perhaps.

Smokin’

Prior attempts were good, but this batch seems especially tasty. Maybe that’s because of the meat slicer acquisition. Uniform pieces make me feel professional…and bring back nightmares from a certain prior job. Worth it.

Thick bacon! Not that sissy store crap.

There we have it: good food, normal ingredients. And while much of my cooking may have peasant origins, I can at least claim proper execution and variations in method. But more importantly, I’ve learned to appreciate the result, not the quantity, of the final dish. Perhaps I’m a true foodie after all.

–Simon