A house!

After my recent accomplishment of finally installing bathroom ductwork into proper external vents, I started to reminisce. We will soon hit our 10-year mark in this house, Easement Acres. What began as an American dream turned into a parenthood want: a place for the kid to grow up. And the romanticized homestead activities of decorating and gardening. I wanted a home. I moved a lot myself as a kid, with the longest stint in a Lubbock property – more of a prison, really, with a tiny backyard and a lack of permission to ever venture beyond the privacy fence unescorted. All it needed was some concertina wire to complete the feeling.

But now, with the decade landmark in sight, this will be the longest I have ever lived in one domicile. So I wanted to look back on what I’ve written about in my time here. Or more specifically, what I’ve written about regarding the house itself.

Here’s a chronological list:

2017

- Wifi and Ethernet

- WFH in my basement setup

- Splitting trees removed by BP

- Sump pump drainage

- Gardening and more trees removed

- Rain barrel

- Rain barrel #2

- Deck staining

- Lamppost

- Hostile neighbors

- Hanging pictures

- Basement growing

- Electrical outlet install

- Putting wire on the fence

- New TV stand

- Live Christmas tree

2018

- Live Christmas tree cleanup

- Ring doorbell camera install

- Gas leak

- New trees planted

- Ozone-ing the carpet

- Revised basement workstation

- Workout equipment acquired

- Hallway carpet replaced with laminate

- War on dandelions

- Property survey

- First reel mower

- Exploding electrical outlet

- Storm door install

- Grandfather clock acquired

- Basement aquarium acquired

- Front porch light install

- Dining room carpet replaced with laminate

- Fence repair after ice storm

- Ethernet patch panel install

2019

- Air purifier acquired

- Revised basement workstation again

- Wired basement desk with ethernet

- Backyard Ring camera install

- Sump pump drainage upgraded with brick

- Lounge carpet replaced with laminate

- Foyer tiled

- Copper cock added to roof

- Rain barrel #3

- Sliding backdoor shattered

2020

- Sliding backdoor replaced

- Second reel mower

- Barn star acquired

- Wine cellar acquired

- Bedroom carpet replaced with laminate

- Garage workshop pegboard acquired

- Dead spruce trees removed

- Retrofitted attic fan install

- Neighbor’s plywood palace and city complaint

2021

- Wood burner install

- Front door lock replaced

- Decorative external shutters replaced

- Security film installed on garage window

- Brick garden edging install

- Garden trellis installed to block view of problem neighbor

- Additional garage organization

- Built the garage door open sensor/indicator

- Roomba vacuum acquired

2022

- Bathroom fan replacement

- Bathroom fan remodel (For some reason, I didn’t post once on this project. I must have been trying to wipe it from my memory).

- Broken chest freezer turned into a root cellar

- Clematis planted on garden trellis

- Easement Acres name formalized

2023

- Garden Ring camera install

- Deck string lights upgraded

- Built deck gate

- Built backyard trellis

2024

- Removed unnecessary bathroom light fixture

- New couch acquired

- New HVAC

- Mosquito wars

- Easement Acres signage

- Hurricane damage

- Bench vise acquired

2025

- Bathroom grips install

- New oven acquired

- More trees planted

- Zombie door

- Ox yoke hung

- New roof

- Built firewood holder

2026

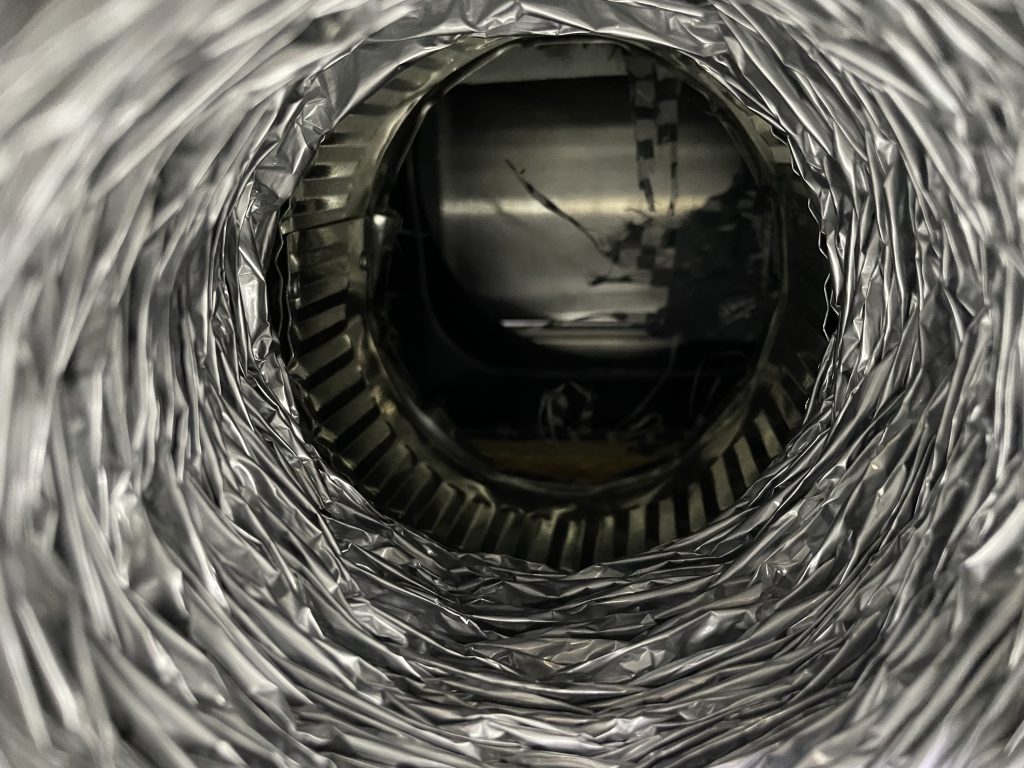

- Attic bathroom ventilation ductwork install

Conclusion

A lot of work has been done here on Easement Acres! It’s definitely more than my parents had ever done to their home. I think the difference lies with the generation gap. My home was never a given. There was a lot of doubt we’d ever get to have one at all! So every day is a new opportunity to, again, partake in the ultimate hobby! It’s not simply a place to live.

I wonder what the next 10 years will bring.

–Simon