Of all the decisions I begrudge my parents for, vehicle availability ranks high on that list. I can get over a lot of things, and being a parent myself now, I understand that money is always limited and decisions have to be made. However, once that lesson is understood, it confuses me as to why parents would decide to have more than one child when they can ill-afford the first. But three? Even the wealthiest of my contemporaries rarely go that route. A third child is usually an accident or a surprise twin.

But: Catholicism. Organized religion has a remarkable inability to consider a more modern quality of life. It makes sense to encourage a population to have many kids when the goal is to grow the community and half of children die before age 5. And in a time predating birth control (or even after it became available but the church prohibited it), it probably didn’t require much encouragement anyway for young couples to engage in more sex – for God, and the community, of course.

Anyway, speaking of quality of life and vehicles, here are some activities directly tied to available transportation in one’s formative years. More specifically, if one doesn’t have access to a car in the suburbs:

- Dating – difficult (unless of course you’re a girl and find a boyfriend with a car, as my sisters did)

- Extracurricular activities – difficult and always needed a cranky parent

- Working – difficult

- Finding a job that actually pays well and offers a career – impossible

- Feeling like a total loser – at least this one’s very easy

Overcoming this barrier was eventually possible when my future father-in-law sold me his old Corolla, which I then unceremoniously lost to black ice on one of the worst damn on-ramps in the state. Fortunately, the insurance payout gave me a down payment for my truly first car (I don’t consider the Corolla to be a first car): a used 2003 Honda Accord, which I proceeded to drive for the next 18 years, ultimately naming it: Old Blue.

Unsurprisingly, I never became a luxury car type of person. Possessing a car at all was my luxury, and an economic utility vehicle that consistently maintained its basic functions was sufficient.

But Old Blue’s age has shaken my confidence in this later quality. I no longer feel that it will always work in a time of need, and repairs are getting numerous and costly. Its latest issue is a rusted exhaust line, which I exacerbated by driving over a snow mound and ripped open. Now the engine exhausts under the hood, which wafts into the cabin, not to mention bypassing the muffler so it sounds like one of those small penises you hear at night playing Toretto. I’ll get that fixed eventually, but for now I needed something more reliable.

I wanted a station wagon. I wanted a car with a car’s chassis – not the typical SUV/crossover standard that everyone seems to make now. Or as I call it: do you want a long turd or a short turd? Seriously, they all look the same, with that turd-shaped aerodynamic (analdynamic?) profile. Bend over and think of England, fellow motorists. And with Liz’s Ascent, we don’t need another type of such a vehicle. One anal probe per family is adequate. I want an actual car, but with the cargo space and convenience of an anal probe…I mean hatchback.

This limited my options. Volvo apparently still makes station wagons, though I’ve never seen a new one. And Mercedes makes one, but I’m not ready for that cost. So, a non-station wagon non-anal-probe-hatchback car. That leaves compacts. And with that comes certain problems, notably image and demographic appeal.

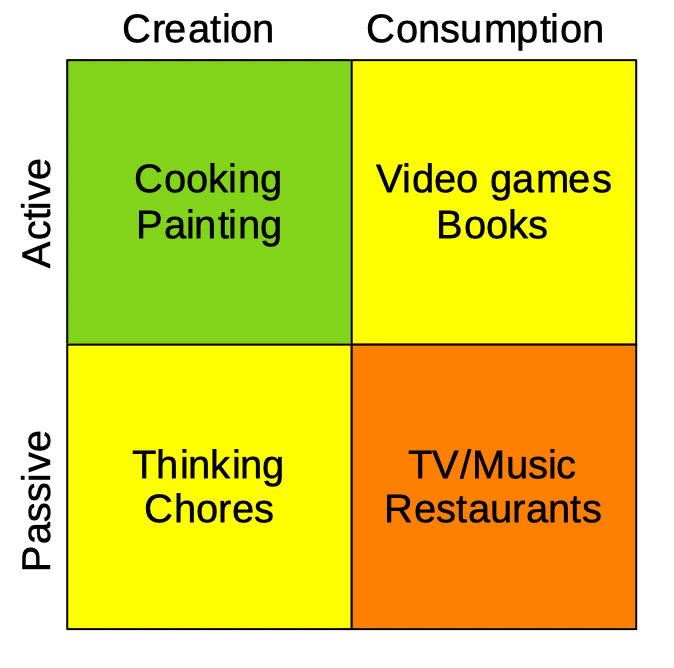

Here’s what I’ve come to accept are the two types of people who buy compact hatchbacks:

This tends to lead manufacturers into douchey territory, with trim and accessories. When’s the last time you saw a hatchback white Honda Civic and one of the above stereotypes didn’t come to mind? What to do?

Here’s what’s on offer today:

- Honda Civic – Absolute no for both the reasons above, my relationship with the local dealership, and past experience with their modern vehicles.

- Toyota Corolla – Lower horsepower and front wheel drive only – nah.

- Mazda3 – I drove one of these as a rental and really liked it. It was underpowered, but I didn’t know which version I had. It was worth considering, except…

- Subaru Impreza – Standard AWG with higher HP on the RS model, and despite past misgivings with the Ascent, the dealership was completely accommodating with repairs and warranties and rentals. Top contender.

And fortunately, Subaru has thoughtfully separated out their douchey demographics into their WRX category, which is a souped-up Impreza. If you go on Reddit and read Impreza reviews, you’ll very quickly encounter some comment about how the poster should have bought a WRX, because that’s a “real” car, for which aftermarket douchebag add-ons have flooded online retailers. Want a spoiler with a wide muffler while pretending to be Formula One Frank and cranking RPMs with a turbo late at night? WRX.

So I went with the Impreza. The 2026 Impreza RS, to be specific. Old Blue’s 160HP always felt just a tad underpowered on hard accelerations, so I wasn’t keen on the Impreza Sport’s 150HP. Granted Old Blue was old and no doubt lost some HP over the years, but even so, I wanted a little more power. The RS’s 180 HP so far seems to fill that gap with just a bit more oomph. And the top-tier model for the Impreza line comes with some luxury additions that certainly don’t hurt – like everything the automotive industry has done within the last 23 years. Seems there’s been some technological advances.

It’s also my first new car! It only had 8 miles on it when I test drove it. So just a couple other butts have been in there. No chance of anything weird that I don’t know about that’ll fail unexpectedly in the future.

And it’s all mine and no one can touch it!

Okay, that’s not true. Part of the reason for getting it was so the kid would have a small and easy car to learn how to drive with, equipped with all the modern safety features. But that’s a year away, and for now it’s all mine! Then once she learns how to drive, she can have Old Blue. It might be a beater, but I won’t leave my own kid without a personal transportation option.

–Simon